“Science and imagination build the best combo.”

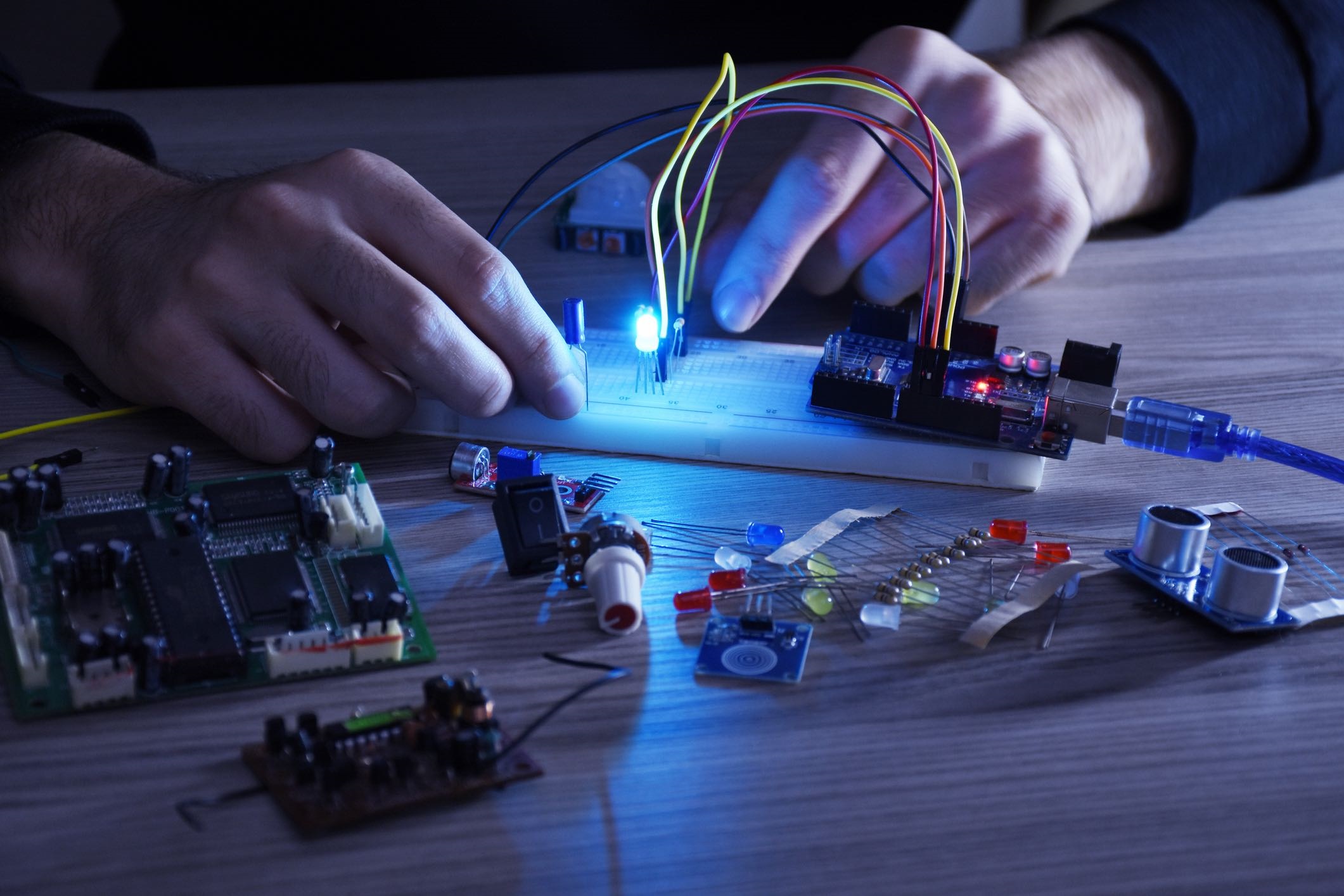

DUST CLEANER

May 2020An environment-friendly dust cleaner has been introduced in this project. The heavy dust particles separate as the high-velocity, dusty air suddenly changes velocity. We attempted to implement this principle into practice by designing the dust separator. However, the smaller and lighter dust particles were separated using regular filter paper. An exhaust fan dragged air into the cooling chamber. While entering the cooling chamber, air changes its direction twice and the heavy particles not being able to keep up with the air gets accumulated in the bottom chamber. We used two dust sensors, one at the entrance and another after the filter paper for monitoring the dust quantity and comparing the data. For measuring the temperature and humidity of the clean air, we utilized a temperature and humidity sensor. To bring the hot clean air into the comfort zone, we developed a closed circulating water cooling system using a water container, a Peltier, a CPU cooler, and a radiator. Finally, we built a water cleaning system to sweep away the heavy dust particles.

SHELL AND TUBE HEAT EXCHANGER

Dec 2020The U-tube shell and tube heat exchanger presented in this project was designed and optimized to cool marine oil using seawater. This type of heat exchanger is one of the most adaptable heat exchangers and is frequently used for industrial applications. We used Soliworks for designing the physical model in our project. Our designed model had a horizontal single shell and double pass tube configuration. The thermal design of a shell and tube heat exchanger typically includes the determination of heat transfer area, number of tubes, tube length, diameter, tube layout, number of shell and tube passes, tube pitch, number of baffles, and its type and size, etc. For thermal calculations we used HTRI software, considering Counterflow, passing hot oil in the tube, and cold seawater on the shell side. We applied the TEMA type "AFL" construction standard to our design. Finally, we performed an economic analysis for optimization of the designed heat exchanger in our project.

COOLING LOAD ESTIMATION

Jul 2021This project presents the cooling load estimation of a typical living room. Based on the equipment present in the living room, the outer space configurations, the window positioning and materials, the door materials and size, the roof and floor materials and arrangements, and the time of the day the cooling load varies significantly. In real life, for proper design and selection of an air-conditioning system, the cooling load estimation is a prerequisite. So, I attempted to gain practical project experience through this project.